Comparison of surface treatment processes for tool storage cabinets: Powder coating vs electrophoresis

When choosing the surface treatment process for tool storage cabinets, powder coating and electrophoresis are two common options. These two processes each have their own advantages and disadvantages and are suitable for different application scenarios and requirements. This article will make a detailed comparison between powder coating and electrophoresis processes to help you make an informed decision.

First, comparison of process flows

(1) Powder coating

Pretreatment: Firstly, clean the metal surface to remove oil stains, rust and impurities to ensure it is clean.

Drying: Dry the cleaned metal parts to remove surface moisture.

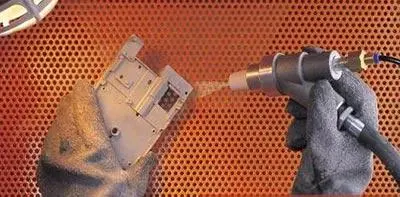

Spraying: Use electrostatic spraying equipment to evenly spray powder coatings onto the metal surface. Powder coatings are adsorbed onto the metal surface under the action of static electricity, forming a uniform coating.

Curing: After spraying, the metal parts are placed in a high-temperature oven to melt and solidify the powder coating, forming a firm coating.

(2) Electrophoresis

Pretreatment: The metal surface also needs to be cleaned to ensure it is free of oil stains, rust and impurities.

Electrophoretic coating: Metal parts are immersed in an electrophoretic tank, and the electrophoretic coating is evenly deposited on the metal surface through the action of an electric field. Electrophoretic paint forms a uniform coating under the action of an electric field.

Post-treatment: After electrophoresis, the metal parts need to be washed with water and dried to remove the excess coating on the surface and cure the coating.

Second, comparison of advantages and disadvantages

(1) Powder coating

Advantages:

Uniform coating: Powder coating can form a uniform coating with controllable thickness, generally ranging from 60 to 120 microns.

Rich in color: Powder coatings come in a variety of colors and textures to meet different appearance requirements.

Good environmental friendliness: There is almost no solvent evaporation during the powder coating process, which is environmentally friendly.

Wear resistance and corrosion resistance: Powder coatings have excellent wear resistance and corrosion resistance, making them suitable for use in harsh environments.

Disadvantage:

High equipment cost: Powder coating requires professional spraying equipment and ovens, with a relatively large initial investment.

Difficulty in color change: The color change of powder coatings requires the replacement of powder, which is relatively complicated to operate.

(2) Electrophoresis

Advantages:

High coating uniformity: Electrophoretic painting can produce uniform coatings with controllable film thickness, generally ranging from 10 to 35 microns.

High adhesion and rust prevention: The electrophoretic coating has strong adhesion, high rust prevention, and excellent resistance to salt spray corrosion.

Good permeability: Electrophoretic paint can penetrate into the complex structure and crevices of the coated object, making it suitable for workpieces with complex shapes.

Good environmental friendliness: The solvent content in the electrophoresis bath solution is low, which is less likely to cause fire and explosion. Moreover, the wet paint film after electrophoresis can be sealed and washed with UF solution to reduce pollution.

Disadvantage:

Material limitations: Electrophoretic coating is limited to the coating of conductive materials and is mainly suitable for metal parts.

Curing temperature requirements: Electrophoretic coating requires a relatively high curing temperature and has poor adaptability to materials sensitive to thermal baking.

Color limitations: The color of epoxy-based cathodic electrophoretic coatings used as primers is relatively monotonous, and there are significant limitations in color coating.

High production cost: Once the electrophoresis line is in operation, it generally cannot be stopped easily, and it is advisable to operate at full capacity as much as possible; otherwise, the production cost will increase.

Third, comparison of applicable scenarios

(1) Powder coating

Application scenarios: Powder coating is suitable for tool storage cabinets with high requirements for coating thickness and wear resistance. For instance, for tool storage cabinets that need to be used in harsh environments or frequently moved, powder coating can offer better protection.

Appearance requirements: If there are high demands for the appearance of the tool storage cabinet, such as requiring multiple colors or textures, powder coating is a better choice.

(2) Electrophoresis

Application scenarios: Electrophoresis is suitable for tool storage cabinets with high requirements for coating uniformity and adhesion. For instance, for tool storage cabinets that require high rust resistance and corrosion resistance, electrophoresis can offer more uniform protection.

Complex structure: If the structure of the tool storage cabinet is complex, with many gaps and inner cavities, electrophoresis can better cover these areas and provide comprehensive protection.

Powder coating and electrophoresis are both excellent surface treatment processes for tool storage cabinets, each with its own advantages and disadvantages. The advantages of powder coating lie in its uniform coating, rich colors, good wear resistance and corrosion resistance, but the equipment cost is high and color change is difficult. The advantages of electrophoresis lie in its high uniformity of coating, strong adhesion, high anti-rust ability, good permeability and good environmental friendliness. However, it has material limitations, high curing temperature requirements, significant color limitations and high production costs.

When choosing the process, a comprehensive consideration should be made based on the specific usage scenarios, appearance requirements, budget and production conditions of the tool storage cabinet. If higher wear resistance and a wide range of appearance options are required, powder coating is a better choice. If better coating uniformity and adhesion are required, electrophoresis is a more suitable choice.

It is hoped that the above content can help you better understand the comparison between powder coating and electrophoresis processes, and thus make the most suitable choice for your needs. If you have any questions about the surface treatment process of the tool locker or need further information, please feel free to contact us at any time.